The rapid development of technology has led to aluminium housings now being used more often in electromechanical products, electronic instruments, mobile power supplies and photoelectric lighting. The aluminium housing not only plays an external protective role, but also makes full use of the space to play a role in heat dissipation. And in the production process of the aluminium shell, it needs to be surface processed. So what are the surface machining methods of aluminium shells? The surface machining methods of aluminium shells are as follows.

1、Polishing

The use of mechanical, chemical or electrochemical methods to reduce the roughness of the aluminum shell surface to obtain a bright and smooth surface. Polishing technology is mainly divided into mechanical polishing, chemical polishing and electrolytic polishing. After mechanical polishing and electrolytic polishing, the aluminium parts of the car can be close to the stainless steel mirror effect, giving a feeling of future advanced simplicity and fashion.

2、Sandblasting

The process of cleaning and roughening the metal surface by the impact of high speed sand streams. Through this method of surface treatment of the aluminium housing, a certain degree of cleanliness and different roughness can be obtained on the surface of the aluminium housing, improving the mechanical properties of the workpiece surface, thus improving the fatigue resistance of the workpiece, increasing the adhesion between the workpiece and the coating, extending the durability of the coating film, and also facilitating the flatness and decoration of the coating. We often see this process in solar bezels and increasingly in existing TV housings or centre frames.

3、Drawing

Metal brushing is the process of repeatedly scraping lines out of aluminium sheets with sandpaper. Wire drawing can be divided into straight drawing, random drawing, spiral drawing and thread drawing. The metalworking micro-content is rich and worthy of attention. The metal brushing process clearly shows every tiny line mark, resulting in a matte glowing metal with a fine hair sheen and a product that blends fashion and technology.

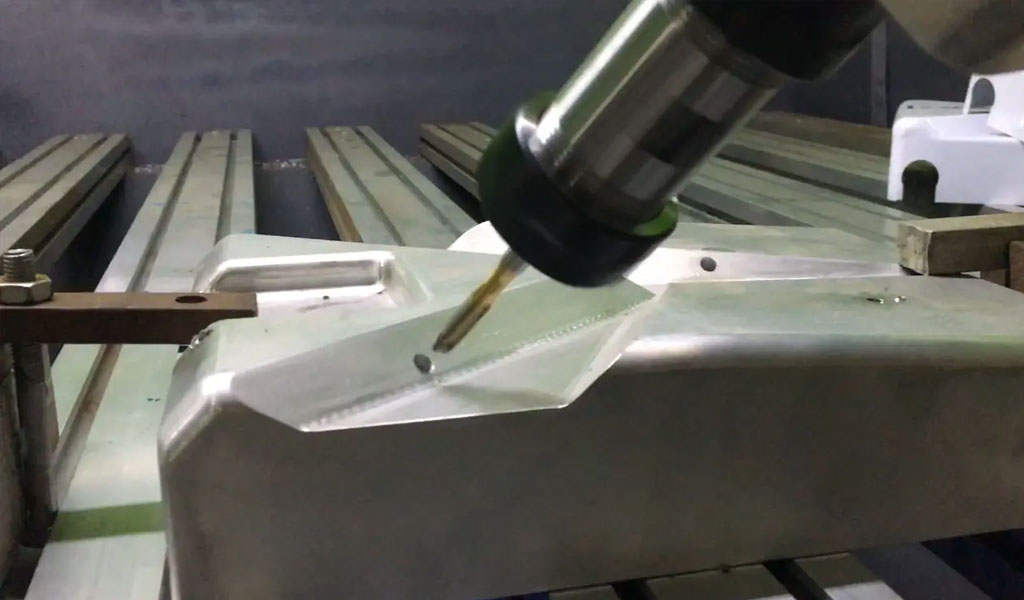

4. Intense light cutting

The diamond cutter is reinforced by the finishing machine to cut parts on the spindle of the finishing machine which rotates at high speed (typically 20,000 rpm ), thus creating localised highlight areas on the product surface. The brightness of the cutting highlights is influenced by the speed of the milling cutter. The faster the drill speed, the brighter the cutting highlight and conversely, the darker the cutting highlight and the easier it is to produce the cutting pattern. Highlight cutting is commonly used in mobile phones. In recent years, some high-end TV metal frames have adopted high-gloss milling technology, together with anodising and brushing technology, making the TV overall stylish and technical.

5、Anodising

Anodising is the electrochemical oxidation of a metal or alloy. Under the corresponding electrolyte and specific process conditions, aluminium and its alloys form an oxide film on the aluminium product (anode) under the action of an applied current. Anodising not only solves defects in the hardness and wear resistance of the aluminium surface, but also extends the service life of the aluminium and enhances its aesthetic appearance. It has become an indispensable part of aluminium surface treatment and is a widely used and successful process at present.

6、Double-colour anodising

Two-colour anodising is the process of anodising a product and giving a different colour to specific areas. Two-colour anodising is a complex and costly process. However, by comparing the two colours, it better reflects the high-end and unique appearance of the product.

The above surface machining methods for aluminium housings are shared here, a good aluminium housing, not only in the face of the excellent, in the texture of the people also love. In short, the use of suitable surface machining methods to process aluminium housing will make your products a lot more colourful, natural value will also increase.