List CNC machine tools and basic manufacturing equipment as “strategic areas to accelerate breakthroughs”, which proposes to strengthen forward-looking deployment and breakthroughs in key technologies, actively plan to seize future technological and industrial competitive manufacturing points, and improve the level of international division of labor and the right to speak. The proposal of this strategic goal is determined by the strategic characteristics and development stage characteristics of CNC machine tools and basic manufacturing equipment industries. We should study and understand it carefully and implement it thoroughly.

CNC machine tools and basic manufacturing equipment have the industrial characteristics of strategic competition

Anchor the global competitive position of my country’s equipment manufacturing industry

CNC machine tools and basic manufacturing equipment are the “working machines” of the equipment manufacturing industry. The technical level and product quality of a country’s machine tool industry are important symbols to measure the development level of its equipment manufacturing industry. “Made in China” 2025 will combine CNC machine tools and basic manufacturing The equipment industry is listed as one of the strategic areas of China’s manufacturing industry. The main reason is that it has an “anchor” effect on the position of a country’s manufacturing industry, especially the international division of labor in the equipment manufacturing industry: CNC machine tools and basic manufacturing equipment are manufacturing The foundation of industry value generation and the fulcrum of industry leaps are the core of basic manufacturing capabilities. Only with solid basic manufacturing capabilities can it be possible to produce advanced equipment products, thereby realizing the production of high-value products.

Support the strategic needs of national defense and industrial security

In terms of national defense security, CNC machine tools and basic manufacturing equipment have a strategic place beyond economic value for the manufacture of advanced national defense equipment. The materials, structures, and processing techniques of many key components in modern national defense equipment have certain particularities and processing difficulties. Common processing equipment and traditional processing techniques cannot meet the requirements. Multi-axis linkage, high-speed, and high-precision CNC machine tools must be used. In order to meet the processing requirements. Even in today’s global integration, developed countries still adopt technological blockades and restrictions on our country. In terms of industrial security, with the acceleration of the upgrading of the domestic manufacturing industry, the competition between high-tech and high value-added industries represented by the equipment manufacturing industry has intensified with developed countries, and construction machinery, electrical machinery, and transportation equipment are entering the international high-end market. However, there are still certain gaps in domestic machine tool products in terms of machining accuracy, reliability, efficiency, automation, intelligence and environmental protection, which leads to the weak competitiveness of the industry as a whole.

An important support for the transformation and upgrading of the user field

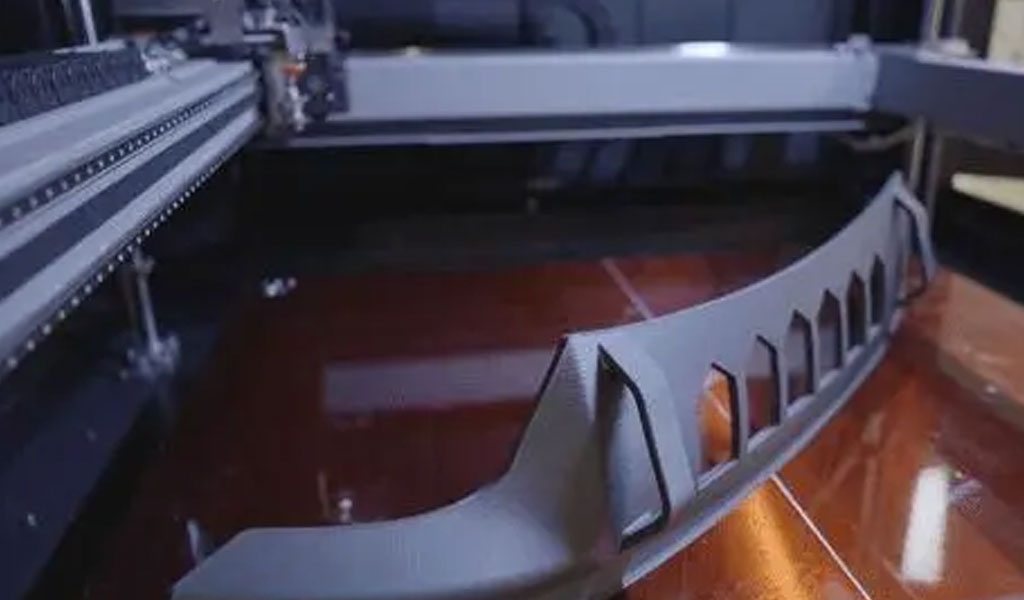

The current demand structure of downstream users in the machine tool industry is showing a high-end development trend. Many industries will undergo large-scale and in-depth structural adjustments and upgrades. There is an urgent demand for high-quality and high-tech machine tool products. Generally speaking, medium and high-end CNC The market demand for machine tools is rising rapidly, and users need more high-speed, high-precision, compound, flexible, multi-axis linkage, intelligent, high rigidity, and high-power CNC machine tools. For example, the automobile industry shows the development trend of producing large quantities, multiple varieties, and fast model updates, and the development of new energy vehicles is accelerating, which requires the continuous development of processing equipment in the direction of precision, efficiency, and intelligence. In the aerospace industry, with the sharp increase in the demand for civil aircraft and the intergenerational development of military aircraft, the new generation of aircraft is moving towards lightweight, high reliability, long life, high stealth, multiple configurations, fast response and With the development of low-cost manufacturing and other directions, the new generation of technology urgently needs more advanced processing equipment to carry it, and aviation manufacturing equipment is developing in the direction of automation, flexibility, digitalization and intelligence. For example, in the aircraft engine manufacturing that the “Two Machines Project” is committed to making breakthroughs in, typical parts such as engine blades, casings and blisks are gradually developing towards larger sizes, complex shapes, lighter structures and more precise manufacturing. In particular, a large number of new lightweight materials such as high-strength high-temperature heat-resistant alloys are used. The geometric configuration of these integral structural parts is complex and difficult to process, which puts forward new and higher requirements for high-torque, high-precision CNC machine tools. Portability or movable multi-axis linkage CNC equipment required for large-scale structural parts of gas turbines and large-scale equipment off-site maintenance. This processing method of processing large workpieces with small machine tools that have no fixed base and can be reconfigured and grouped has a great impact on the new CNC. The structural design, process specifications and high-energy-efficiency processing technology of equipment pose greater challenges.

It is the strategic highland of the new technology revolution

The elements of intelligent manufacturing, energy Internet and new generation information technology innovation contained in the new round of scientific and technological revolution provide driving force for technological breakthroughs in China’s equipment manufacturing industry, and also provide a huge market for equipment manufacturing, especially high-end equipment manufacturing. The machine tool industry It is an important intersection of information technology and industrial technology. The industry itself has a strong sensitivity to new technologies and is also the main source of emerging technology diffusion. Driven by the wave of new technology revolution, the trend of integrated innovation in the machine tool industry is obvious. The world’s leading companies accelerate the integration of new technologies into the machine tool industry, and the integration and application of network technology and intelligent technology into machine tool products. Parts companies and complete machine companies are accelerating the integration and application of new technologies in CNC machine tools.

The strategic fulcrum for the adjustment of the global manufacturing industry pattern

Entering the post-crisis era, developed economies have paid attention to the development of their own real economy: or continue to promote the integration and development of emerging technologies and promote the high-end industrial technology; or through the restructuring of the industrial chain, let more high value-added manufacturing links and jobs returned to the homeland. The United States has successively proposed the implementation of the “Advanced Manufacturing Partnership Program” and the “National Strategic Plan for Advanced Manufacturing” to develop advanced manufacturing and technology; Germany has proposed the development blueprint of Industry 4.0, and is committed to developing with CPS as the core and smart factories as the carrier. German Industry 4.0, and positioning it as a technology platform for a new round of industrial revolution; Japan announced its industrial structure blueprint, identified 10 cutting-edge technology fields, and strengthened domestic manufacturing based on this; the United Kingdom, South Korea, India, China Taiwan Regions such as China have also proposed active strategies and policies to promote the accelerated integration of emerging technologies in equipment industries such as CNC machine tools. The machine tool industry has always been an important strategic layout point for major countries and leading companies. In the future, the manufacturing industry will change and adjust, especially for high-strategy industries such as global automobiles, aerospace, and high-end equipment manufacturing. The machine tool industry is an important strategic fulcrum. It plays an important role in the future competitiveness of the leverage. my country should strengthen the emphasis on the machine tool industry, lay out key strategic areas in advance, and strive for a favorable position for the global competition of the manufacturing industry.

The trend of industrial upgrading is obvious

Make breakthroughs in key core technologies and form a batch of iconic products

In the field of aviation, we have independently developed heavy-duty forging equipment such as 800MN large-scale die forging presses and 120MN aluminum alloy plate tension stretching machines, which have filled the gap in the overall forming technology of large-scale critical parts in the domestic aviation field, and provided for the cross-generational development of military aircraft and the development of large aircraft. a strong guarantee. Among them, the 800MN large-scale die forging press has realized the overall forming of more than 30 key parts of titanium alloys in the aviation field, and the high-quality aluminum alloy thick plates produced by the 120MN aluminum alloy wide and thick plate tension stretching machine have been applied to the main bearing force of aircraft wings. Structural components have got rid of the dilemma that my country’s large aircraft aluminum alloy plates are completely dependent on imports.

In the field of automobile manufacturing, the large-scale fast and efficient CNC automatic stamping production line has won the batch order of the production line of the local automobile factory in the United States in the international bidding with world-class enterprises, and has been recognized and respected by the international counterparts. At present, the domestic market share of automobile panel stamping lines exceeds 70%, and the global market share has exceeded 30%, which has effectively promoted the self-reliance of domestic automobile equipment.

In the field of power generation equipment, the 36,000-ton black vertical metal extrusion machine has realized the independent production of domestic high-end heat-resistant steel large-diameter thick-walled seamless steel pipes used in 1000MW ultra-supercritical thermal power units; the large-scale split heat treatment equipment has produced Asia’s largest Forgings of nuclear power integral forging rotors have formed the mass production capacity of large rotors; super-heavy CNC vertical turning-milling compound processing machine tools developed for third-generation nuclear power nuclear islands and conventional island equipment, CNC heavy-duty bridge-type gantry five-axis linkage turning-milling compound machine tools , ultra-heavy CNC floor milling and boring machine, ultra-heavy CNC horizontal boring lathe, special CNC axial wheel slot milling machine, etc., which solve the processing problems of nuclear power pressure vessels and hanging baskets, heat exchangers, steam turbine cylinders, generator rotors, etc. Installed and applied on multiple nuclear power equipment.

Optimized and adjusted the product structure, and steadily improved the technical level

First of all, the level of medium and high-end equipment has been rapidly improved. At present, more than 10 types of equipment, such as the automatic stamping line for large-scale automobile panels, have reached the international leading level, and can completely realize import substitution. More than 20 types of products, such as high-speed gantry five-axis machining centers, have basically reached the international advanced level and are capable of replacing imported products. The precision horizontal machining center forms the core technology of a flexible manufacturing system with independent intellectual property rights. High-end CNC machining centers such as high-speed and composite have completed phased research and development, but there is still a certain gap between them and the international advanced level in terms of functional performance and reliability. Secondly, the numerical control system moves forward step by step. my country has made considerable progress in the research and development of medium and high-end numerical control systems. Since 2010, it has realized more than 35,000 domestically produced medium and high-end numerical control systems in key fields such as aerospace, energy, ships, and automobiles. substitute. Multi-channel, multi-axis linkage and other high-performance CNC system products have broken the monopoly of foreign technology, and the main technical indicators have basically reached the level of international mainstream high-end CNC systems, and have realized supporting a variety of high-speed and precision CNC machine tools. The high-end numerical control system has been applied in small batches in key military enterprises. The developed standard CNC system has achieved mass production, and the domestic market share has increased from 10% to 25%. Several industrialized production bases have been formed, among which Guangzhou CNC Equipment Co., Ltd. has formed an annual production capacity of 100,000 sets of various CNC systems, ranking second in the world in terms of output. Our country’s CNC system has initially possessed the competitiveness with similar foreign products, and has achieved batch export of CNC systems. From 2010 to 2014, more than 9,600 sets of various CNC systems have been exported, including nearly 700 sets of five-axis linkage CNC systems. Finally, the quality level of functional components has been steadily improved, and the product series have been continuously improved. Domestically produced functional components have been matched with machine tools in batches; tool products have basically been able to provide modern cutting tools for the automotive industry. The application demonstration and batch matching of CNC systems, functional components and tools with CNC machine tool hosts will help form a complete industrial chain and promote the structural adjustment of the machine tool industry.

Significant improvement in independent innovation and sustainable development guaranteed

In recent years, machine tool manufacturing foundation and common technology research have been continuously strengthened, and product development and technology research have been promoted simultaneously. The maturity of many key technologies such as reliability design and performance test technology of machine tool products and multi-axis linkage processing technology has been greatly improved. The research results of digital design technology have been applied in the design of high-precision CNC coordinate boring machines, vertical machining centers and other products; software and hardware systems such as multi-error real-time dynamic comprehensive compensation and embedded CNC system error compensation have been applied in multiple enterprises and multiple products Demonstration applications have been carried out, and the precision of CNC machine tools has been significantly improved.

High-end industrial development has a long way to go

my country’s machine tool industry occupies an important position in the world’s machine tool industry system and the global machine tool market, but it still cannot be regarded as a machine tool powerhouse. Compared with the world’s machine tool powerhouses, my country’s machine tool industry still has a certain gap, especially in the low competitiveness of medium and high-end machine tools. In addition, affected by the complex economic situation at home and abroad, the development of my country’s machine tool industry has returned to the new normal, and there is an urgent need for the industry to transform and upgrade to mid-to-high end.

International competitiveness needs to be improved

According to the statistics of the consulting agency Gardener, in the world machine tool consumption market, my country’s machine tool exports in 2014 were 3.3 billion US dollars, accounting for less than 5% of the world’s total machine tool consumption; while Japan and Germany both accounted for more than 10%. At the same time, a considerable part of the high-end and high-end CNC machine tools urgently needed in the country relies on imports, such as imported equipment in the automotive field accounting for more than 40%.

The development of key components in the machine tool industry needs to be strengthened urgently

Domestically produced functional components cannot meet the matching requirements of the main engine in terms of variety, quantity, and grade, and the market share of domestically produced mid-range supporting functional components still needs to be improved; high-end products largely rely on imports. The competitiveness of supporting functional parts industry needs to be improved rapidly.

Process verification and demonstration applications need to be strengthened

From prototype development to actual production application, CNC machine tools need to undergo a large number of experimental verifications in terms of manufacturing process, reliability and precision retention, engineering, etc., and continue to improve. At the same time, users need to provide process verification. The process verification and application demonstration is also a shortcoming in the development of china cnc machining machine tool industry.

Industrial development pressure remains high

Global machine tool production and consumption continue to show a shrinking trend. According to the data released by Gardner Corporation of the United States, the global machine tool consumption in 2014 was 75.3 billion US dollars, an increase of only 0.3% compared with 2013. The global machine tool production has declined for three consecutive years. %, China CNC machine tool industry also continues to operate under pressure, and is in a downward range as a whole. In 2014, the output of domestic metal processing machine tools decreased by 2% year-on-year, among which, the output of metal cutting machine tools decreased by 1.7% year-on-year, and the output of metal forming machine tools decreased by 3.3% year-on-year. At the same time, the demand for imported machine tools in the domestic market has risen instead of falling. In 2014, the total import of machine tools was 17.78 billion US dollars, an increase of 10.8% year-on-year, of which the import value of metal processing machine tools was 10.83 billion US dollars, an increase of 7.6% year-on-year. It is difficult for the domestic machine tool industry to meet the high-end needs of enterprises. The domestic machine tool industry is under the double superposition of cyclical pressure and structural pressure, and it is urgent to find a new development breakthrough.

Accelerate the promotion of the strategic thinking of making the industry bigger and stronger

Promote the focused development of advantageous resources

On the basis of improving the independent innovation capabilities and market competitiveness of domestic CNC machine tools and basic manufacturing equipment, promote superior resources to focus on the two major fields of aerospace and automobiles, focus on core equipment and key technologies, and focus on solving the performance reliability and stability of research and development equipment Bottleneck issues of key technologies such as compatibility and completeness.

Promote the demonstration application of advanced products

Increase investment in the construction of application verification and application demonstration bases that are representative of user needs and can centrally verify key technologies and core equipment of machine tools and basic manufacturing equipment, and selectively support market-oriented product sets, high flexibility and intelligence project, focusing on the efficiency and intelligence of equipment

To meet the new needs of the national strategy

Accelerate the development of national strategic development needs CNC machine tools and basic manufacturing equipment, further focus on the core equipment of national key projects, develop major products, and break through key technologies. Efforts should be made to improve the technical level of CNC equipment and break the restriction of national strategic equipment relying on imports.

Create a complete machine tool supporting industry chain

Encourage and support CNC machine tools and basic manufacturing equipment hosts, CNC systems and functional components and other related units in the industrial chain to form long-term and stable strategic partnerships, establish long-term supporting relationships between CNC systems, functional components and machine tool companies, and create a complete CNC machine tool and foundation Manufacturing equipment supporting industry chain.