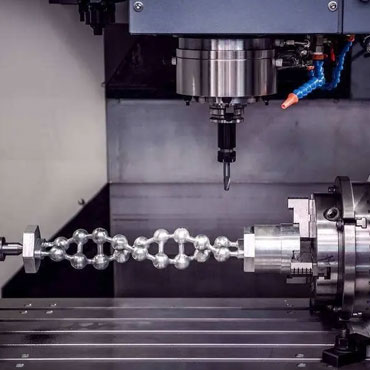

4 Axis CNC Machining

4-Axis milling involves the same process involved in 3-axis machining, where cutting tools are used to remove material from the workpiece to create the desired shape and contour. However, in 4-axis machining, milling is carried out on an additional axis. a 4-axis CNC machine runs on the X, Y and Z axes like a 3-axis machine, but it also includes rotation around the X axis (called the A axis). This is the 4th axis that is added to our machining process.

In most cases, the workpiece will rotate to allow cutting around the B axis.Four-axis milling is useful when holes need to be punched or cut out in the sides of the workpiece or in a cylinder. They can provide fast and efficient work based on digital input from the computer, resulting in accurate results.

Maximum 4 Axis CNC Machining Capabilities at Wonder

Our experienced 4 Axis CNC Machining engineers can select the right tools and optimize tool paths, achieve an ideal 4 Axis CNC Machining face, and keep tight tolerances. We can provide all types of custom CNC machined parts to meet your project needs.If you are having problems getting your 4 Axis CNC Machining parts done, contact us and try to get a solution from Wonder.

| Size Limit | Metric | Imperial |

|---|---|---|

| Maximum part diameter | 431mm | 17 inches |

| Maximum part length | 990mm | 39 inches |

| Maximum swing on carriage | 350mm | 13.7 inches |

| Maximum spindle through hole | 40mm | 1.5 inches |

Learn More About Wonder’s 4 Axis CNC Machining Services

At Wonder, we are proud to provide machining, finishing, mold development, and more for 4 Axis CNC Machining parts. Please explore our 4 Axis CNC Machining services, contact us to learn more about our machining services for 4 Axis CNC Machining parts, or request a quote for further pricing details today.Wonder is your premier source for high quality machining and 4 Axis CNC Machining services.

You can also email at [email protected] for more information.